| |

|

|

| |

Drill Stem Testing Equpment

|

|

| |

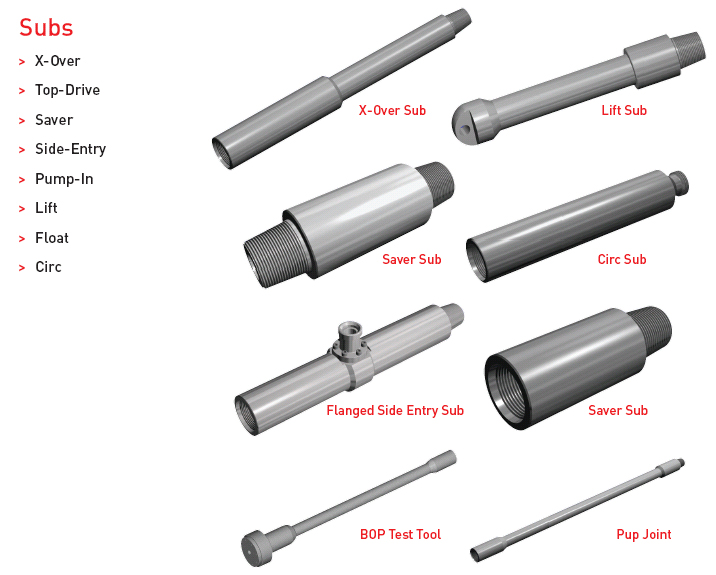

GDESI is well positioned to design and implement any client’s potential drill stem testing (DST) needs. Our expertise covers all major areas of the DST process from drill pipes, bottomhole assemblies, drill collars, to drill bits. Drill stem tests are conducted to in order to gauge the potential productive capabilities of an oil well. In order to test a potential productive area, a DST tool is attached onto a drill pipe and lowered into a potential oil well at which point weight is brought to bear in order to expand the drill stem’s packer, a plug used to test a specific area of an oil well in isolation. After weight has been applied to the packer, the drill stem’s ports are opened and the well’s pressure levels can be gauged through pressure recorders. GDESI does not only provide a full line of complimentary DST tools, but can implement said tools and carry out drill stem testing services as well. What separates GDESI from other DST tool providers, is its ability to design, delivery, and carry out all steps in the DST process.

|

Engineering Procurement & Construction (EPC) / Pipeline

With over a decade of experience in engineering, procurement, and construction, GDESINC has been awarded various EPC projects in Iraq. Thanks to our successful relationships with various engineering firms and oilfield equipment manufacturers, GDESINC is able to provide the Ministry of Oil and various international oil companies with full turnkey solutions to all EPC needs.

|

|

| |

Engineering Procurement & Construction (EPC)The invention comprises a packer design for use in high temperature well bores. The packer is set by pressuring the well fluid through a tubing string, which moves a piston and shoe assembly on the packer mandrel, compressing a non-elastomeric high temperature packer element. The piston and shoe assembly combination is maintained in position after pressure is decreased, and the packer element is maintained in a compressed state by belleville springs which compensate for the lack of resiliency of the non-elastomeric packer element. |

|

|

| |

|

|

|

GEDSI has developed an extensive inventory of new and new surplus drill bits from the worlds leading manufacturers. If we do not currently have the bit your project requires we have the resources to source, quote, acquire, and ship that product often as quickly as if it had been in our inventory. |

|

|

| |

|

|

| |

|

|

|

|

|

| |

|

|

Horizontal Separator

Instrumented vessel that separates well effluent into three phases for onshore and offshore well testing; can operate as a stand-alone unit or with PhaseTester portable multiphase flowmeter with Vx technology. |

|

|

| |

|

|

| SCRUBBER

GDESI Scrubber specifications:

- Used for Solid / Liquid Separation from Gas Stream.

- Removes Solid and Liquid Particle sizes greater than 10 Microns with 100% efficiency .

- VANE / MESH / Multi-cyclone design.

- Prevents re-entertainment of separated particles.

- Low Pressure Drops.

- Large Collection Volumes.

- Large Size Range.

- Provision for Automated Liquid Level Monitoring & Liquid Removal

|

|

|

|

|

|

|